OIL-510DAutomatic infrared oil analyzer

1. Compliant with national standards

National Environmental Protection Standard of the People's Republic of China HJ637-2018

The Water Quality of Petroleum and Animal and Vegetable Oils

Determination of Infrared Spectroscopy Method ";

2. National Metrological Verification Regulations JJG 950-2012 Water Oil Concentration Analyzer;

Technical principles-1Based on HJ637-2018 "Determination of Water Quality - Petroleum and Animal and Vegetable Oils - Infrared Spectrometric Method". Under the condition that the pH of the water sample is ≤ 2, tetrachloroethylene is used as the extraction agent, and high-speed rotary mixing extraction technology is used to extract the oil substances in the water body with a certain proportion of the extraction solvent. Then, the extraction solvent is dehydrated and introduced into the analysis tank to determine the oil content; After removing polar substances such as animal and vegetable oils by adsorbing the extract with magnesium silicate, determine the petroleum content. The content of oil and petroleum is determined by wave numbers of 2930cm2(CH-1Stretching vibration of C-H bond in functional group), 2960cm3(CH-1The stretching vibration of C-H bond in the functional group and 3030cm

3. Calculate the absorbance A2930, A2960, and A3030 at the stretching vibration of the C-H bond in the aromatic ring based on the correction coefficient; The content of animal and vegetable oils is the difference between the content of oil and petroleum.

application area

4. Used for the determination of petroleum and animal and plant oils in industrial wastewater and domestic sewage.

system composition

preprocessing unit10Equipped with an unlimited injection rotation device, while also storingA sample to be tested,

Support adding water samples midway, the equipment automatically reads the volume of the water sample, automatically adds a quantitative extraction solvent, and uses high-speed rotating mixed extraction technology for water sample extraction. The extraction liquid is automatically separated by an oil-water separation device to remove trace amounts of water, and is adsorbed by magnesium silicate. The adsorbed extraction liquid is transported to the detection unit for detection and analysis. After the analysis is completed, the equipment automatically completes the waste liquid extraction

Discharge and pipeline cleaning work.

detection unit

This unit automatically detects samples from the pre-processing unit and transmits the detection data to the work platform

Data Analysis Unit

This unit consists of a computer and specialized software, used to process data from the detection unit, analyze test results based on given experimental conditions, and output test results in the form of screen display, report printing, etc.Fully enclosed waste liquid treatment unit

:

5. The tested wastewater and waste solvents are automatically emptied into different waste liquid tanks for collection through air flow. There is no residual liquid in the pipeline, which does not affect the testing of the next sample and has no cross contamination; Reduce the amount of waste liquid processed, ensuring safety and reliability; Reduce secondary environmental pollution.

Functional Features

1)10High degree of automation: automatic completion of extraction agent injection, sample extraction, separation, water removal, adsorption, detection, and system cleaning, saving manpower and time;

2) Infinite cycle injection: simultaneous storage

A rotating sample disk for the test sample, supporting the addition of water samples midway;3) Simultaneous processing of multiple samples: With three independent working axes, one sample can be tested while the next sample is stirred and extracted, greatly reducing the detection time for individual samples;4)

High extraction efficiency: using high-speed rotating mixed extraction technology, the extraction efficiency is greater than

98%

;

5)

Good stability: Real time automatic adjustment of the zero point of the analysis unit (eliminating the influence of baseline drift). Computers collect signals when light sources emit light and when light sources turn off, achieving real-time automatic zero point adjustment, simplifying operations, and improving long-term signal stability;

6)

Automatic measurement of water sample volume: Using an ultrasonic water sample volume reading device, it can quickly and accurately complete the measurement of water sample volume. The software can directly read it without manual measurement and input;

7)

Automatic replacement of magnesium silicate: No manual filling is required. Each time it is used, the magnesium silicate storage tank automatically discharges the standard amount of magnesium silicate through a quantitative device. The magnesium silicate particles are fully oscillated and adsorbed with the extraction solution through airflow. After each adsorption, the used magnesium silicate is automatically discharged and cleaned to avoid cross contamination;

8)

Magnesium silicate quantitative device: In order to avoid the impact of magnesium silicate agglomeration on emissions, a magnesium silicate quantitative device has been specially designed. This device can ensure that the magnesium silicate used each time can reach the standard dosage, ensuring saturated adsorption;

9)5000Automatic cleaning and waste discharge: After the test is completed, the waste liquid is automatically discharged and the pipeline is cleaned using an air flow self-cleaning method. There is no residue in the pipeline, and the used stirring rod is automatically cleaned to avoid cross contamination of the sample;

10)Automatic separation of waste liquid: After the extraction liquid is extracted into the separation tube for separation, the liquid to be tested is transferred to the detection unit. The remaining waste liquid is completely separated from water by the separation device and discharged into dedicated waste liquid tanks for collection, avoiding personnel exposure to toxic and harmful gases and liquids;11)Exhaust gas collection system: an independent exhaust gas channel equipped with a dedicated exhaust gas adsorption device. The equipment can adsorb and dispose of harmful gases without placing them in a fume hood, avoiding the harm of toxic gases to experimental personnel;12)

Easy to maintain equipment: With independently designed separation and dehydration technology to remove trace amounts of water from the extraction solution, there is no need to frequently replace anhydrous sodium sulfate, resulting in low maintenance costs, more convenient use, and better maintainability;

13) Comprehensive safety measures: To ensure the safety of experimental personnel operating the instrument, the unit door is equipped with a dedicated infrared sensor. When the door is not closed, the system issues an instruction to stop the rotation of the sample disk to prevent accidents, and reminds the experimental personnel on the software;

14) Moisture proof device: using a dedicated desiccant to automatically absorb water vapor in the air, preventing factors such as magnesium silicate agglomeration and excessive humidity in the pipeline from affecting the test results;

15)

6. The entire system adopts anti-corrosion: anti-corrosion and oil repellent materials are selected to ensure that the system is not corroded, has no residue, and has no cross contamination;

16)-1High performance light source system: specially designed halogen tungsten lamp light source with a lifespan of up to-1More than hours. The light source uses pulse modulation light source technology to prevent high internal temperature of the instrument from affecting stability;

17)

Equipped with dedicated analysis software: a multifunctional software that integrates sample information input, scanning and collection, calculation and analysis. It has obtained a computer software copyright certificate and passed the evaluation of provincial software institutions; Adopting dual system analysis to meet the usage of carbon tetrachloride or tetrachloroethylene as extractants respectively-1

(-1

Test and validation report for tetrachloroethylene issued by a national environmental protection system

)Three measurement indicators: capable of measuring both the content of oil and the content of petroleum, animal and plant oils;18)

Automatic configuration of standard curve: The instrument automatically dilutes the standard solution according to the requirements and detects it, generating the standard curve automatically;19)Automatic dilution: intelligently identify high concentration samples and initiate the automatic dilution process to ensure the accuracy of test results;

20)

Reagent remaining monitoring: Real time monitoring and tracking of reagent usage. When the reagent amount is insufficient, the software automatically reminds and starts the protection mode;

21)

Equipped with dedicated sampler: Randomly equipped with dedicated sampler, sampling bottle and sampling box, the material of the sampling bottle meets the standard requirements and can be directly tested on the machine without transferring the water sample, avoiding sample errors caused by water sample transfer.

Technical indicators and related parameters

1) Wave number range: 3400cm

~2400cm

(i.e. wavelength range of 2941nm to 4167nm)

2) Absorption range: (0.0000-2.0000) AU, which means the transmittance is (100-1)% T

3) Wave number repeatability: ± 0.5cm

4) Wave number accuracy: ± 0.5cm

5) Measurement range: (0-64000) mg/L, can be automatically diluted in excess range

6) Wavelength accuracy:

±

7. 5nm7) Wavelength precision:

|

|

± |

|

|

3nm3608) Ultimate stability (absorbance change within 30 minutes):<0.01AU109) Method detection limit: 0.06mg/L |

|

|

10) Instrument detection limit: ≤ 0.06mg/L (3 times SD of 11 measurements of tetrachloroethylene blank solution) |

|

|

11) Accuracy error: ≤ 1.5% (30 mg/L~50mg/L) |

|

|

12) Linear correlation coefficient: r>0.999 |

|

|

13) Repeatability: RSD ≤ 0.6% (30 mg/L~50mg/L) |

|

|

14) Analysis time: The measurement time for a single sample is 15 minutes (including pre-treatment time), and the subsequent sample measurement time for continuous sample measurement is 10 minutes per sample. It can be stored and continuously measured for 10 samples at the same time |

|

|

15) Sampling volume: (0~600) ml Injection cup (water sample cup with scale) |

|

|

16) Host specifications: 450mm (length) x 400mm (width) x 130mm (height) 12kg |

|

17) Extraction unit specifications: 680mm (length) x 560mm (width) x 650mm (height) 50KG |

18) Interface type: USB 2.0 |

|

19) Power supply: (220 ± 22) V, (50 ± 1) Hz, 550VA 20) Warm |

Degree: (-5~35) ℃21) Relative humidity: (20-80)% OIL-510D |

|

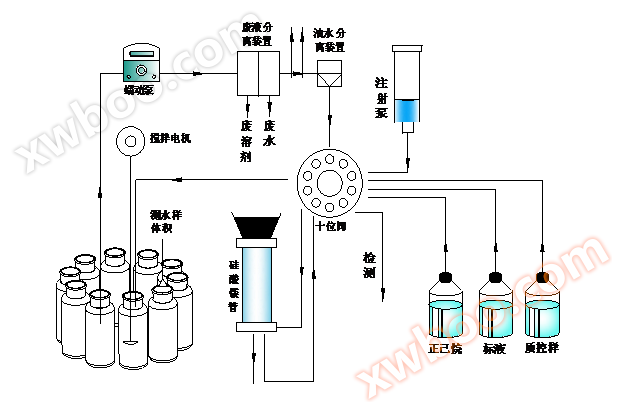

Schematic diagram of pre-processing unit |

Dual mode injection: The fully automatic injection mode or manual injection mode can be quickly switched. The fully automatic injection mode is used to connect the pre-processing unit and achieve continuous testing of multiple samples; Manual injection mode is used for single machine operation and testing after external extraction of a single sample machine.Infinite cycle injection Rotating the sample tray allows unlimited sample injection, supports adding water samples midway, and can be stored simultaneouslyA water sample cup Simultaneously processing three independent working axes with multiple samples can achieve simultaneous stirring and extraction of the next sample while testing one sample, greatly reducing the detection time of a single sample; Ultrasonic automatic detection device for water sample volume, measuring water sample volume quickly and accurately; Brown water sample bottles that meet the standard requirements can be directly used for sampling and machine testing |

|

Separation device: Adopting patented oil-water automatic separation and dehydration technology, it eliminates the need for frequent replacement of anhydrous sodium sulfate and manual removal of clumping in manual methods. It is easier to operate, has low maintenance costs, and is more convenient to use! Magnesium silicate is automatically replaced every time it is used. The storage device automatically discharges the standard amount of magnesium silicate adsorbent through a quantitative device. The magnesium silicate particles are thoroughly shaken and mixed with the extraction solution through airflow to ensure the adsorption effect! Automatically discharge used magnesium silicate after each use and clean the equipment to reduce the risk of cross contamination! |

Automatic preparation of standard curve: It can automatically dilute standard samples and test them, and automatically establish standard curves;To ensure the safety of the experimental personnel operating the instrument, sensors are installed on the switch door. When the door is not closed, the sample stage will not rotate to prevent accidents, and the software will remind the experimental personnel |

|

The moisture-proof device adopts a dedicated desiccant to automatically remove water vapor from the air, visually display the replacement cycle, and avoid the influence of water vapor on the test results |

The exhaust pipeline instrument comes with a fully enclosed ventilation system and exhaust gas collection system, which can solve the harm of harmful gases to experimental personnel without the need to place a fume hoodMain application areas |

|

Execution standards |

Environmental monitoring stations, domestic sewage, and industrial wastewaterdetermine |

|

HJ637-2018 |

Water quality - Determination of petroleum, animal and vegetable oilsinfrared spectrophotometry |

|

Measurement of oil fume emissions in the catering industry |

GB18483-2001Emission standard of cooking fume |

|

HJ1077-2019 Determination of exhaust gas, oil fume, and oil mist from fixed sources of pollution |

infrared spectrophotometryMunicipal Drainage Testing Station Water purification center and sewage treatment plantGB18918-2002 Pollutant discharge standards and other standards for urban sewage treatment plantsMonitoring of external drainage in petroleum, petrochemical, offshore oil development GB3551-83 |

|

Emission standards for water pollutants and other standards in the petroleum refining industry |

|

Railway Environmental Monitoring Station

|

GB5469-85 |

Standard for Discharge of Wastewater from Railway Freight Car Washing and Other Standards |

Environmental monitoring station for thermal power plantsHJ637-2018Water quality - Determination of petroleum, animal and vegetable oils |

|||||||||

|

infrared spectrophotometry |

Monitoring of wastewater in the smelting industry |

GB13456-92 |

Emission standards for water pollutants and other standards in the steel industry |

Agricultural Product Quality Supervision, Inspection and Testing Center |

Agricultural and Forestry Environmental Monitoring Station |

GB5084-92 |

|||||

|

Agricultural Irrigation Water Quality Standards0.05 |

GB4284-840.5 |

Standard values for pollutant control in agricultural sludge and other standards1.0 |

|||||||||

|

HJ637-2018 |

Determination of petroleum in soil |

infrared spectrophotometry |

Scientific research and teaching |

Concentration limits for petroleum in some environmental quality standards and emission standards in China |

Standard Name |

||||||

|

Standard number0.05 |

Concentration limit (unit:0.30 |

mg/L0.50 |

|||||||||

|

) |

environmental quality standards for surface water |

0.3 |

|||||||||

|

GB3838-2002 |

class i |

class ii0.05 |

|||||||||

|

class iii |

Class IV |

Class V |

≤ |

≤ |

|||||||

|

≤0.50 |

Sea water quality standard10.0 |

GB3097-19971.0 |

|||||||||

|

class i |

class ii |

class iii |

Class IV |

≤ |

|||||||

|

≤0.50 |

≤10.0 |

Standards for drinking water quality1.0 |

|||||||||

|

GB5749-2006 |

Water quality standard for fisheries |

GB11607-891.0 |

|||||||||